Knowledge Base

Knowledge Base

Grades and Finishes

Glossary of Terms

Wood Flooring Grades

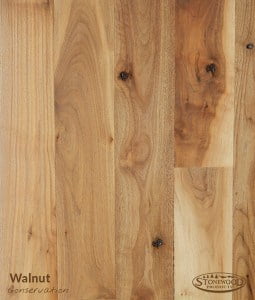

Conservation Grade

Conservation Grade is our most popular. It is milled from high grade lumber from the best mills and is a Select Grade with added character. Slight color variation and selected knots add warmth and beauty to the floor, as well as define appropriate personality – generally offered in medium lengths but inquire about options.

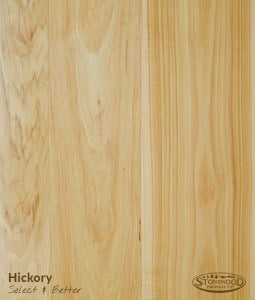

Select and Better Grade

Select Grade Wood Flooring is more uniform with sound knots less than 1/8″ x 1″. Also included are minimal character marks, such as small knots, worm holes, and mineral streaks, as well as slightly open characters. The combination creates a floor where the light sapwood and dark heartwood are combined with small characters and other small color interruptions.

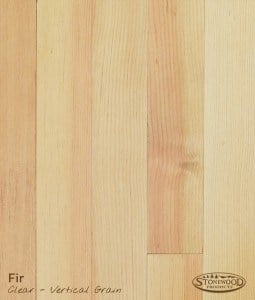

Clear Grade

Clear Grade Wood Flooring contains little to no knots or pinholes or other imperfections and is composed mostly of heart wood. This results in a relatively consistent overall color, clean appearance, and mild character.

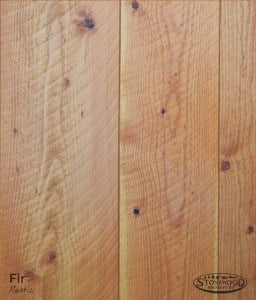

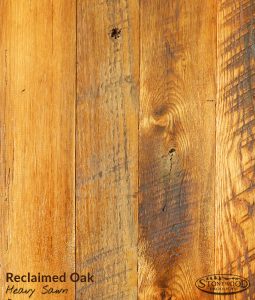

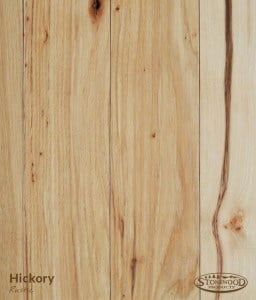

Rustic Grade

Rustic Grade Wood Flooring are generally for those who want heavy character. These floors will typically come in shorter lengths. Beautiful mix of natural colors (heartwood and sapwood). Mineral marks and piling marks are accepted. Knots of up to 3/4″ are filled. Splits, checks are accepted as well.

Wood Flooring Finishes

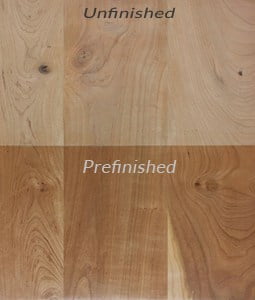

Unfinished Wood Flooring

Unfinished Solid Wood Flooring is mainly 3/4″ thick and is the most common. It offers the ability for staining and many sandings as needed over the decades of use – solid wood floors are usually finished in-home.

Prefinished Wood Flooring

Prefinished Flooring makes it easier and quicker to install. It’s also helpful to minimize dust in an existing house.

In the past, prefinished was associated with bevels and lower quality but not anymore. See our amazing UV oiled prefinished collections to learn more.

Engineered Wood Flooring

Engineered Wood Flooring is the generally the most stable flooring and sometimes recommended if you are installing below grade (ground level) or high moisture areas. It is a solid wood wear layer glued on top of layers of ply.

Engineered Wood Flooring is the generally the most stable flooring and sometimes recommended if you are installing below grade (ground level) or high moisture areas. It is a solid wood wear layer glued on top of layers of ply.

The quality of Engineered Wood depends on the thickness of the veneer ply and the origin of the wood (quality of the mill). We are happy to provide you with the best engineered flooring for many species of floors.

Wood Flooring Sawn Styles

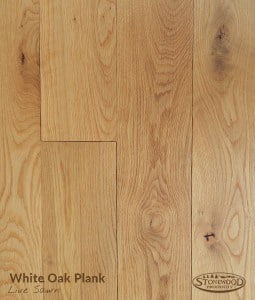

Live Sawn Wood

Live Sawn wood is cut by sawing straight through the diameter of the log. It produces a unique character and grain pattern that was seen almost exclusively for centuries.

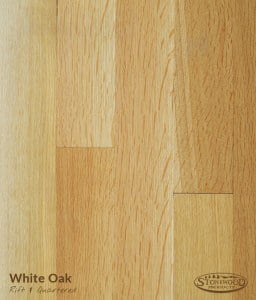

Rift and Quartered Wood

A Rift & Quartered cut is a combination of quarter and rift sawn strips. It sports a straight grain pattern with flecking throughout for an appearance that is truly unique.

Terms and Cuts

Bevel The small gap between floor or wall boards.

Heartwood The dense inner core part of a tree trunk, yielding the hardest timber for lumber and flooring.

Sapwood The soft outer layers of recently formed wood between the heartwood and the bark, that gives the floor or wood its unique character look.

Paneling v Siding Paneling usually refers to wood inside like Wallboarding or bead boards whereas Siding refers to the same for exterior applications.

ECB Edge and Center Bead, a type of pattern with siding.

Patina The unique inherited color of the wood that can be drawn out by finished like Tung Oil.

Live Sawn

Live Sawn lumber is produced by cutting the log straight through it’s diameter, leaving the heart of the log creating less product waste. The unique blend of character and grain lends itself to the way lumber was cut centuries ago.

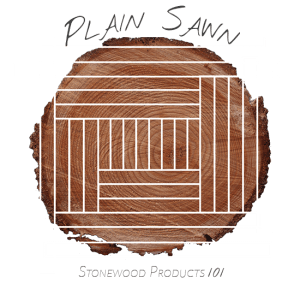

Plain Sawn (aka Flat Sawn) Plain sawn (aka flat sawn) is the most common lumber available. This is the most inexpensive way to manufacture logs into lumber. The annual rings are generally 30 degrees or less to the face of the board. The resulting wood displays a cathedral pattern on the face of the board.

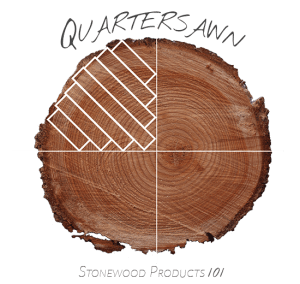

Quarter Sawn QuarterSawn lumber is defined as wood where the annual growth rings intersect the face of the board at 60 to 90 degree angles. Each log is cut into quarters, then boards are cut from the circumference to the center.

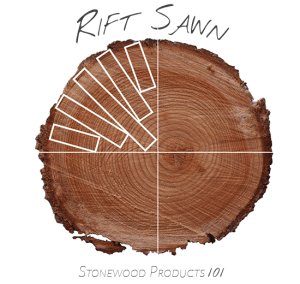

Rift Sawn: Lumber sawn so that the annual rings are typically between 30-60 degrees, with 45 degrees being ideal. Manufactured by milling perpendicular to the log’s growth rings produces a pattern with a linear grain and no flecking.